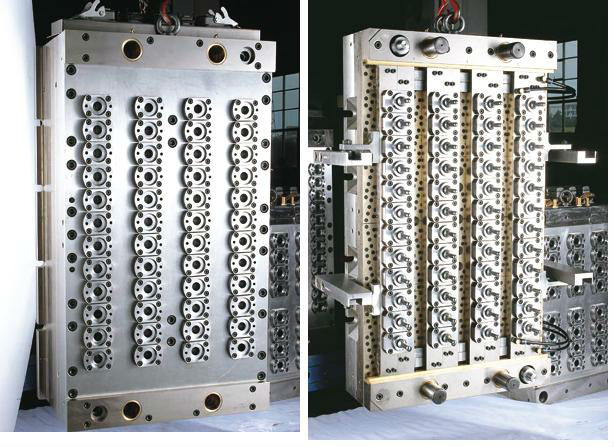

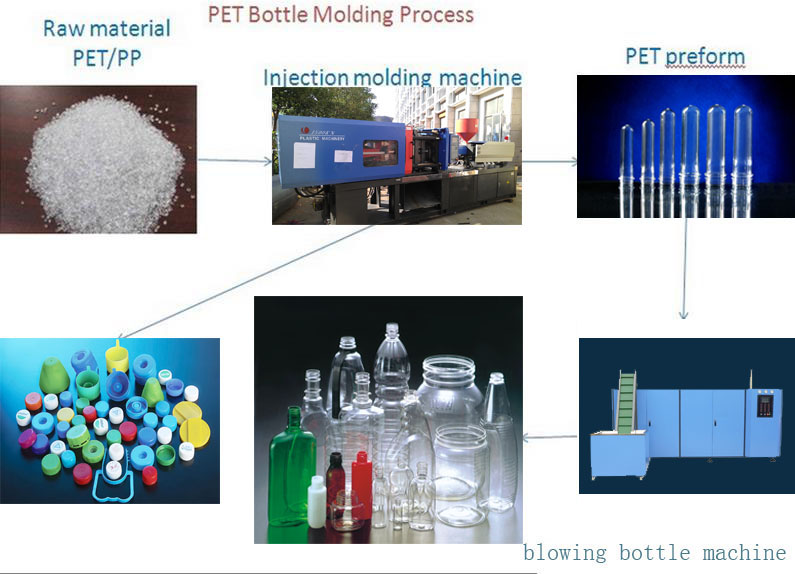

Molde de inyección de preformas de mascotas

Información básica

Modelo: 2-72

Descripción del producto

ProductividadBiciclo rápido debido a circuitos de enfriamiento especialmente diseñados

Sensores de expulsión de piezas que supervisan la transferencia de preformas a la placa de despegue, mejorando el tiempo de ciclo

Componentes de molde intercambiables estándar, piezas de repuesto disponibles en 24 horas

Confiabilidad

Diseño robusto para una vida larga

Cilindros auxiliares que reducen el desgaste del molde al precalenar las mitades del molde antes de que el enganche del anillo del cuello se estreche

Las levas de rodillo accionan tanto las acciones de apertura como de cierre en las divisiones de hilo

Calidad de pieza

El menor peso de la cavidad a la cavidad y la variación dimensional como resultado de las mejores máquinas y procesos de fabricación

Mangueras de agua que están colectadas en la parte inferior del molde de preforma de canal caliente, eliminationg potencial para marcas de agua en preformas

PET Preform Mould Main Components Specification and Advantages | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Main component |

Specification and Advantages |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Core |

2316 steel from Sweden |

high-quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Neck |

S136 steel from Sweden, HRC >60, International standard screw neck |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

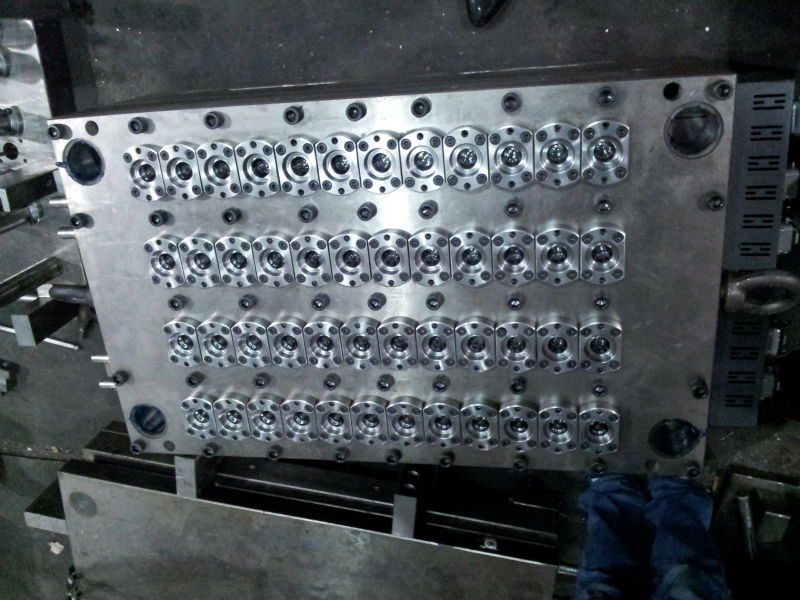

Cavity |

2316 steel from Sweden Each cavity have an independent temperature controller Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Body |

P20 Steel material from Germany |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot runner plate |

2344 Steel material from Germany

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Slider Plate |

wear-resistant copper |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

specially designed cooling circuits |

Proper design reduce molding cycle time to 15 seconds( with proper water chiller and injection machine) about 3-5 shots per minute |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hot runner design |

make sure the high quality of preform products. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heater |

Anole Germany |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

valve gated design with Automatic drop |

each cavity has its independent heating zone and temperature is measured by independent thermocouple. .(advantages: easily avoid some problems such as white or draw bench on bottom). Valve gated type without tail reduces labor force. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Precessed by high presion CNC machine and numerical control loathe machine |

Lowest weight and dimensional variation thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well Fast cycling due to specially designed cooling circuits Part ejection sensors that monitor preform transfer to the take-off plate,improving cycle time Standard interchangeable mold components,replacement parts available within 24 hours Reliability Rugged design for long life Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers Roller cams actuate both the opening and closing actions on the thread splits Part quality Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes Water hoses that are manifolded at the bottom of the hot runner preform mould,eliminationg potential for water marks on preforms

DATOS DEL MOLDE

Grupos de Producto : Molde de preformas Premium Related Products Otros productos

Productos hot 200t máquina de moldeo por inyección de mano / botella de moldeo por inyecciónMolde plástico de la inyección, molde plástico, molde de la preformaMolde de inyección de 28mmplastic / molde plástico de la preformaMáquina de llenado automática botella de 5 galones de PETSistema de ósmosis inversaDiseño de la botellaMolde de la tapa de la botella de 48 cavidadesMáquina de soplado de dos cavidades semi automáticaMáquina de moldeo por soplado totalmente automática (6 cavidades)Máquina de moldeo por inyección de tubo de pvc 438tonsMáquina de moldeo por inyección de plásticoMáquina de moldeo por inyección precio HDX2000 IIBOTELLA PET PREFORMA INYECCIÓN MOLDEADORA HDX208PET PARA PEQUEÑO VOLUMENlistos alta calidad del molde de preformas de PET hechoJeringuilla desechable de la venta caliente de la alta calidad HDJS128 que hace la máquinaMáquina de moldear por inyección | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||